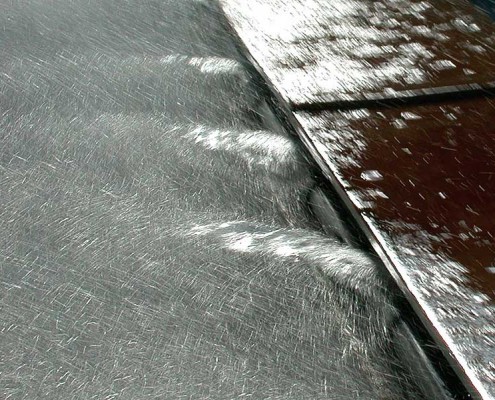

Surface Treatment of Aluminium

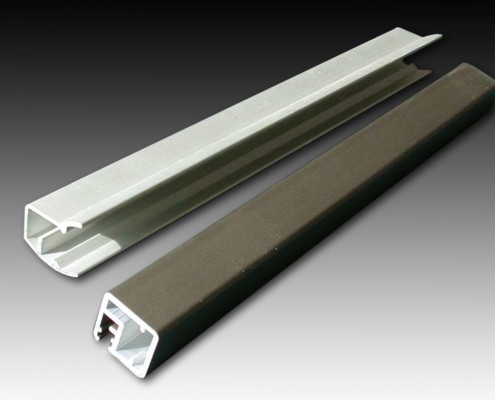

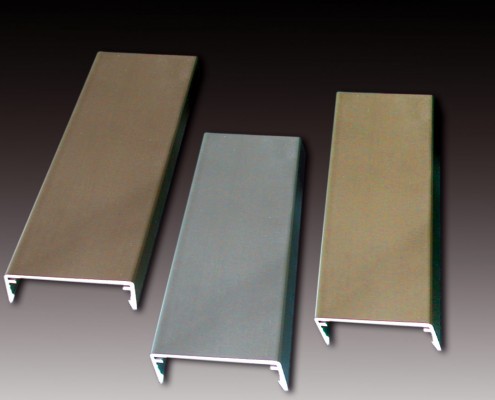

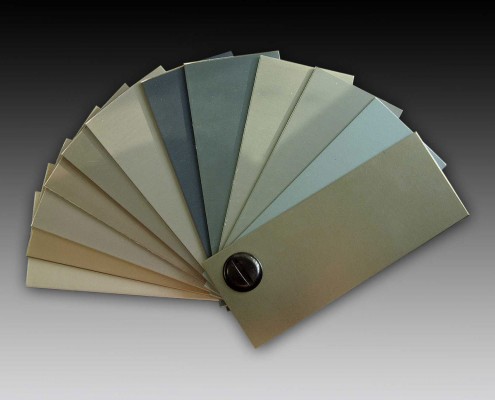

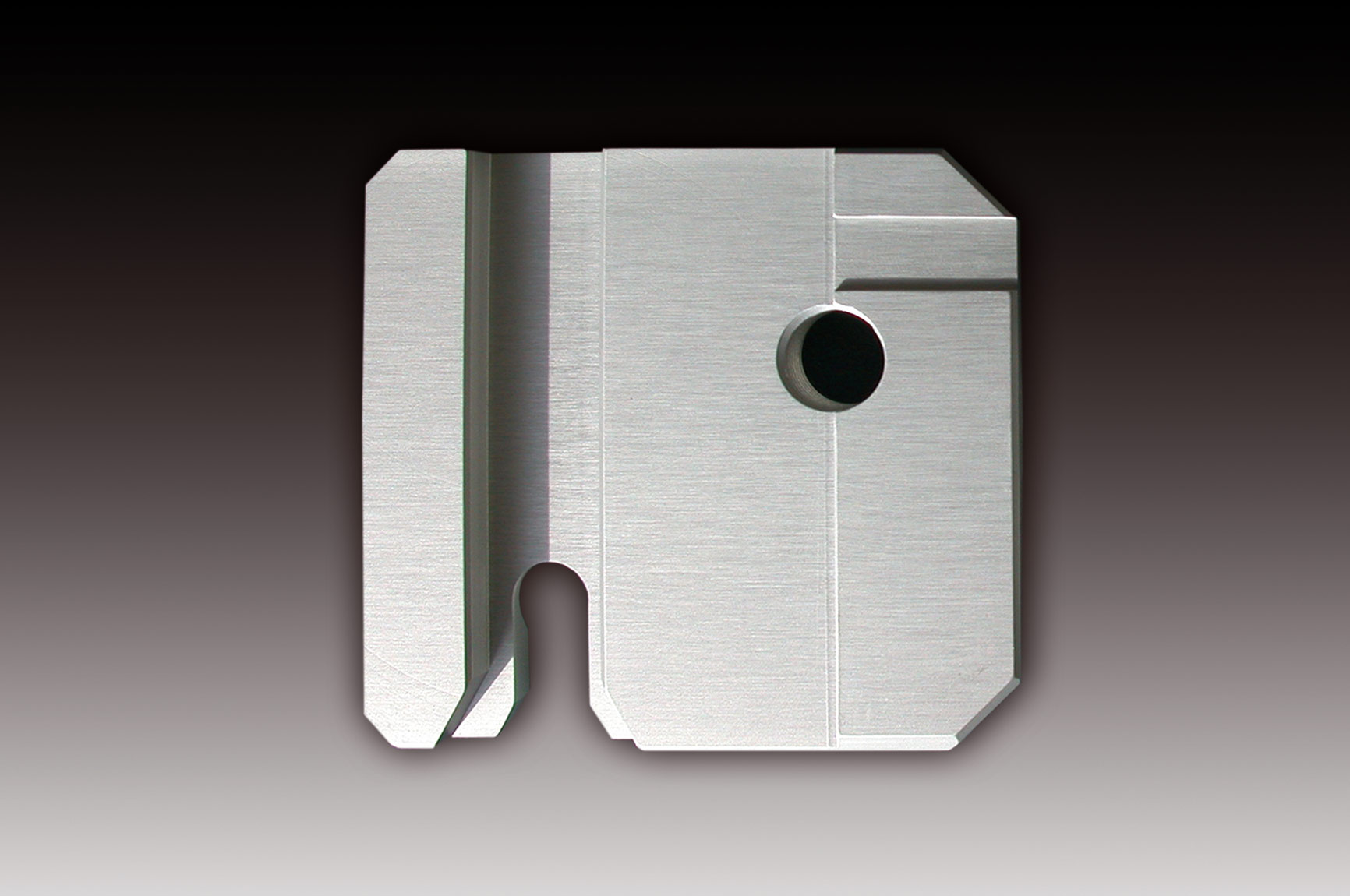

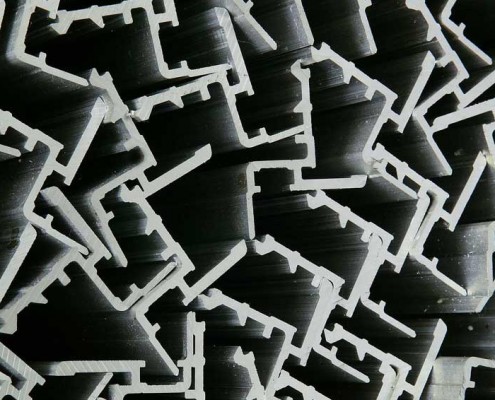

From architecture to medicine devices, from machinery to sports equipment, from automotive to aircraft building: aluminium fulfils most the specifications needed. Your application determines the choice of surface treatment, whether as technical specification or as visual impression of the final product.

The processes are fixed and described as standards internationally. Although there are additional ambitious quality specifications in the field of anodising and powder coating created by quality label organisations.

Have a look at our certificates.